novaphit®

Graphite gaskets

High-quality gaskets made from expanded graphite

The novaphit® product family comprises a range of high-quality expanded graphite flat gasket materials – made in Germany. novaphit® gaskets are reliable and durable even at the outer application limits, which makes them the perfect choice wherever excellent efficiency and performance paired with maximum process reliability are required.

novaphit® gaskets have the following properties:

- Temperature range from -200°C to 550°C

- Universal chemical resistance

- Excellent adaptability to flange unevenness

- Insensitive to changing loads

Future applications with hydrogen

In the future, Frenzelit will mark products suitable for hydrogen applications with a registered H2 - logo. Materials and products marked as "H2 - approved" have been tested in both resistance and leakage tests with the medium hydrogen and their suitability has been proven.

- novaphit® MST

- novaphit® SSTCTA-L

- novaphit® SSTC

- novaphit® SSTCTRD 401

- novaphit® 400

- novaphit® VS

- novaphit® M

- novaphit® M REEL

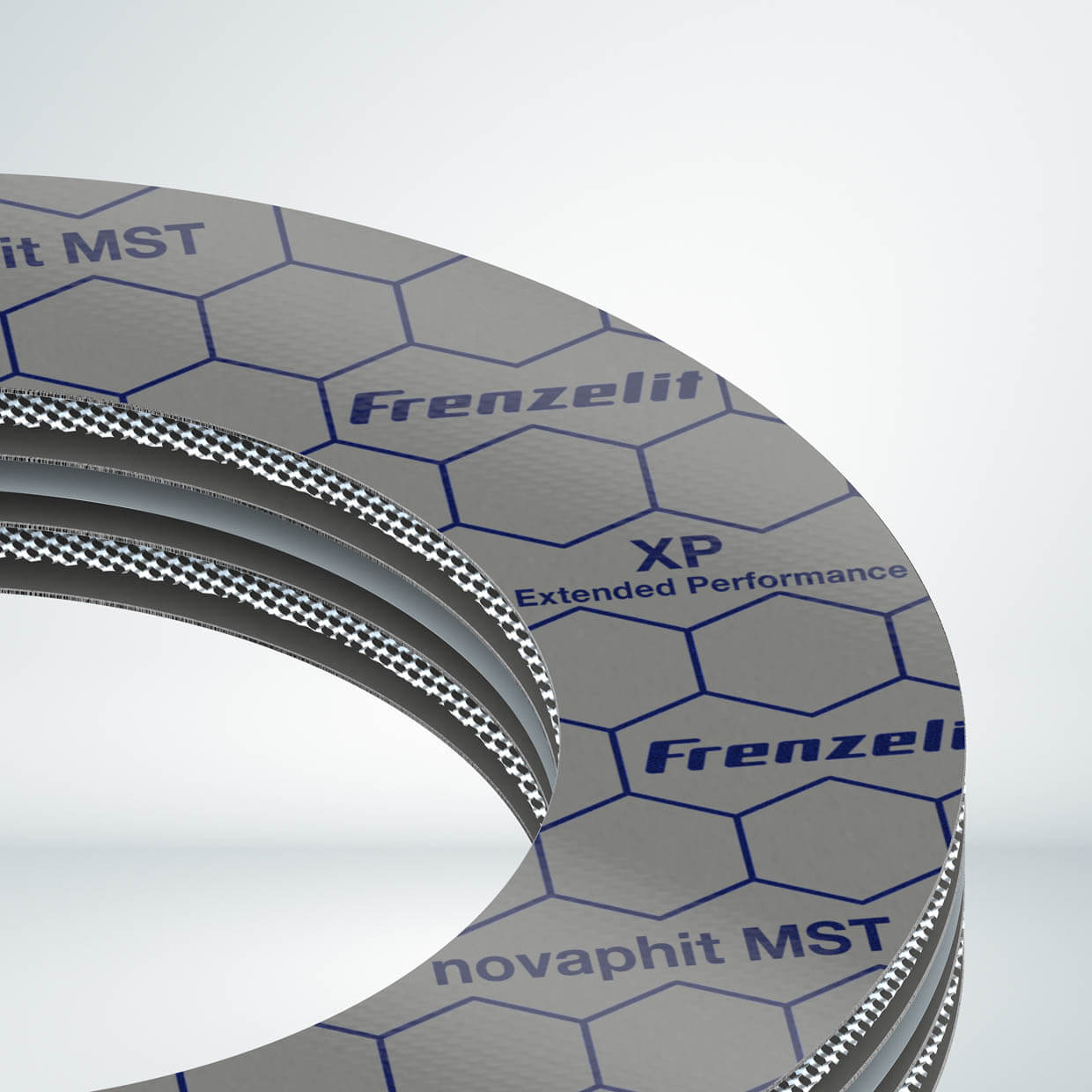

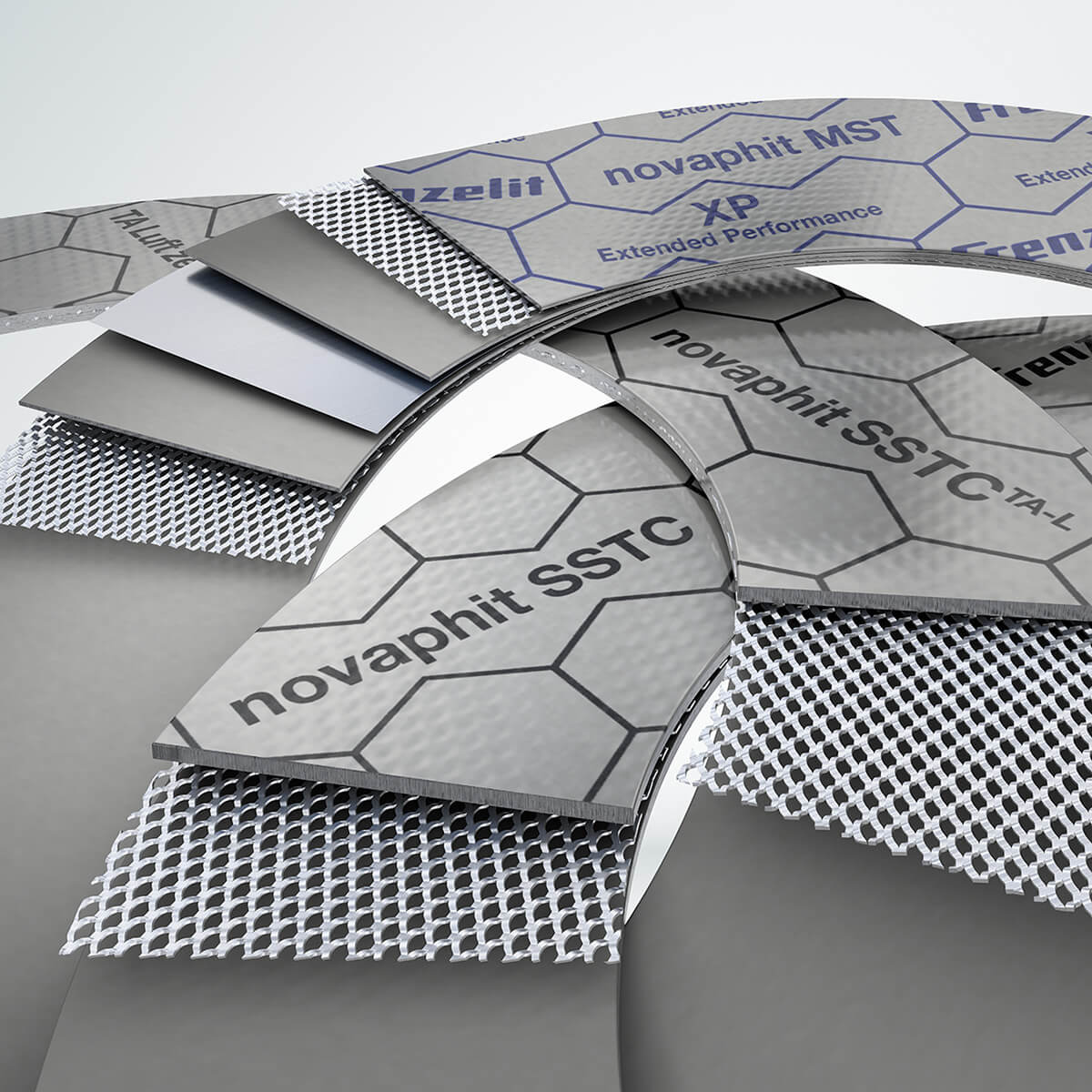

High-performance gasket with multilayer structure

novaphit® MST stands for the highest performance. This material combines highly pure, premium-quality graphite foils with multiple layers of perfectly coordinated expanded metal and flat metal inserts (up to eight graphite layers and seven inserts depending on the material thickness). This material structure creates unique mechanical properties with the lowest leakage values and guarantees excellent performance in use.

novaphit® MST’s multilayer concept provides optimum handling and allows extremely high pressure and temperature loads – even under changing load conditions. Thanks to its sophisticated layered structure, novaphit® MST can withstand above-average surface pressures and even extreme pressure loads (internal pressure up to 250 bar).

novaphit® MST is extremely dimensionally stable and can be easily processed using all standard methods – even manually on site. Its outstanding adaptability means that novaphit® MST forgives installation errors and even compensates for damaged flange surfaces.

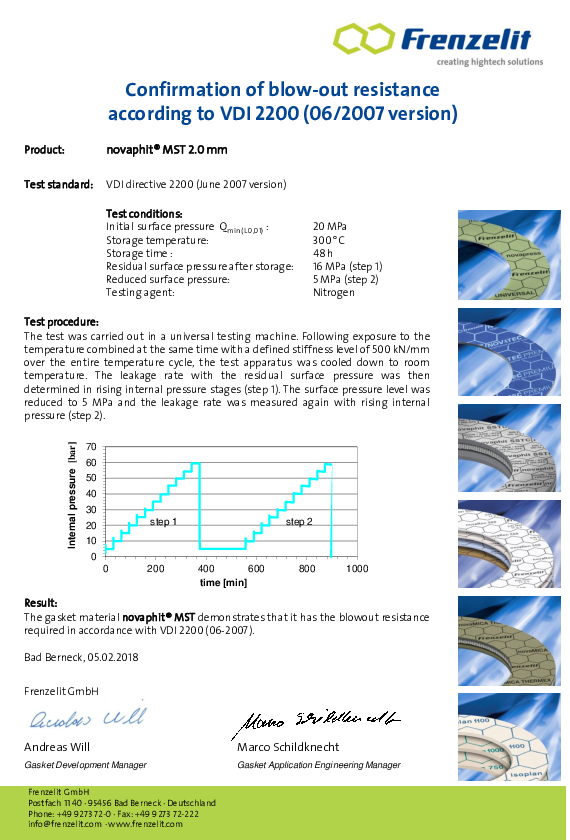

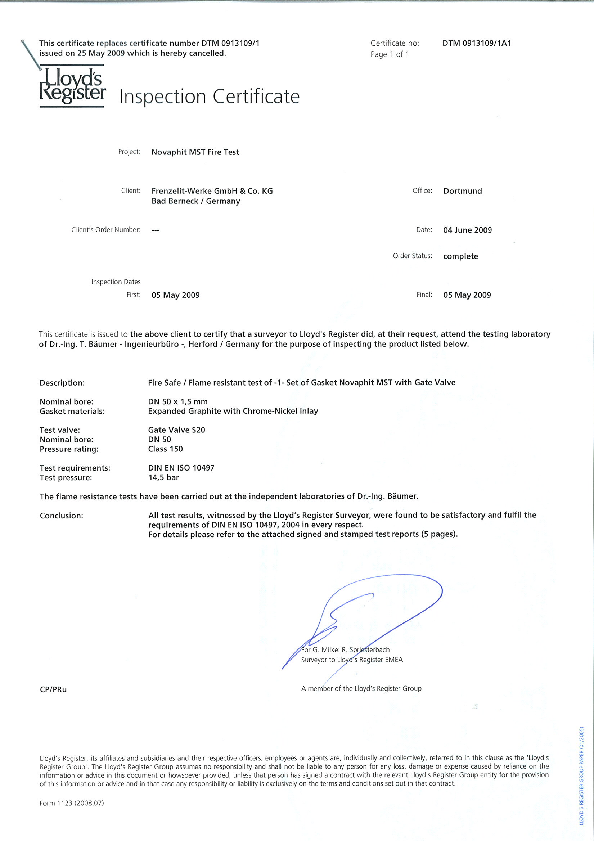

novaphit® MST meets the most stringent requirements with regard to preventing diffuse emissions and is considered “high quality” in terms of TA Luft. Thanks to its superior performance, novaphit® MST makes it possible to produce gasket connections in compliance with the strict criteria of TA Luft and VDI 2290. It goes without saying that all required gasket parameters are available according to DIN EN 13555. This makes useful, real-world designs possible according to DIN EN 1591-1.

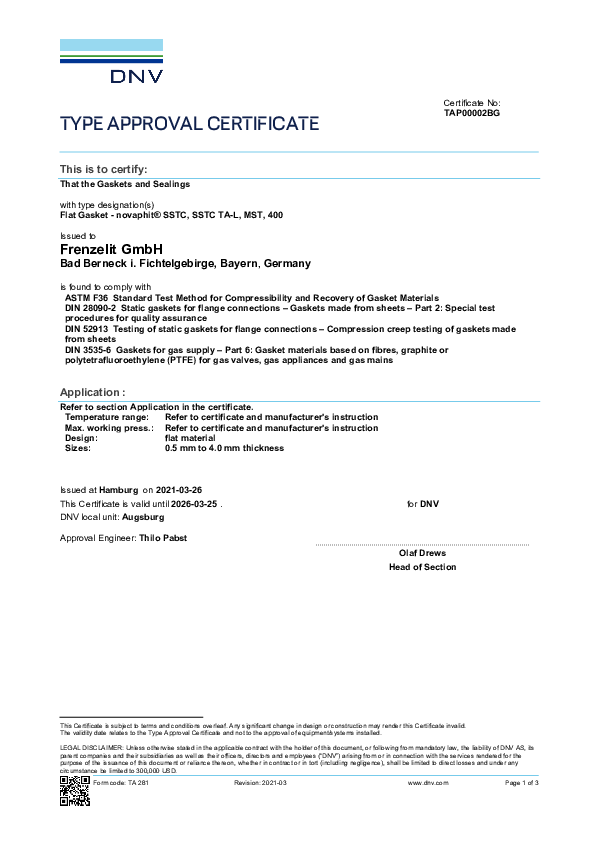

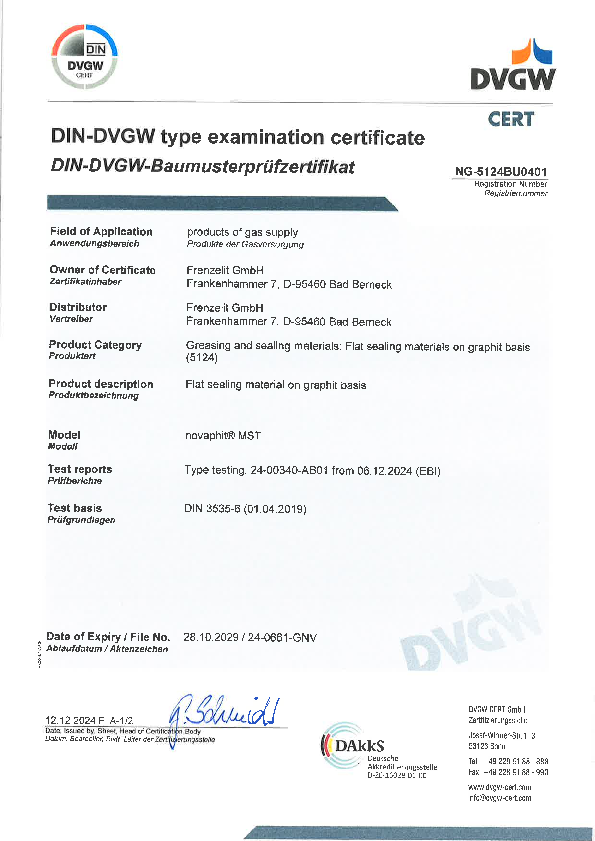

Further approvals make novaphit® MST the ideal all-round, one-size-fits-all solution for the entire plant. You’re definitely on the safe side with novaphit® MST!

XP technology is standard in novaphit® MST, giving it increased oxidation resistance and optimized anti-stick properties.

Brochure, technical data sheet and characteristic values

High-quality graphite gasket in terms of TA Luft

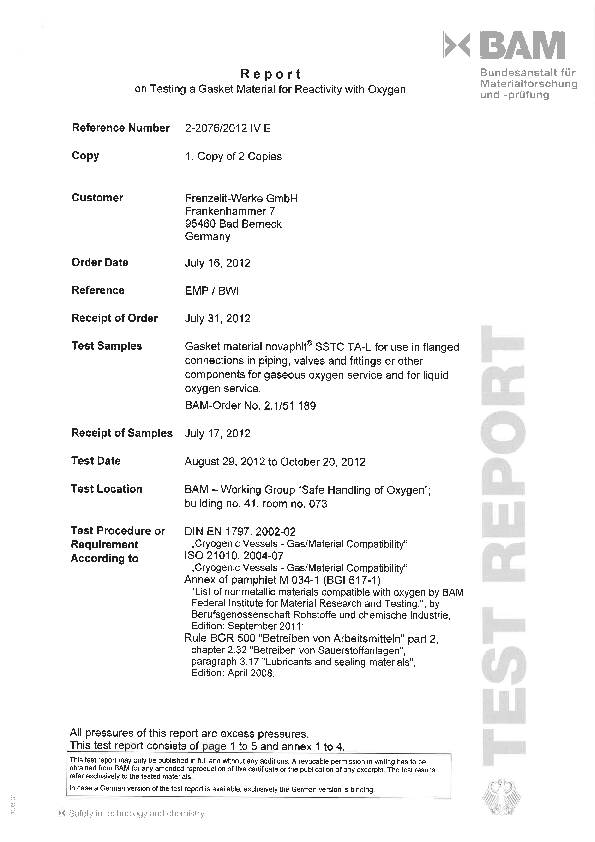

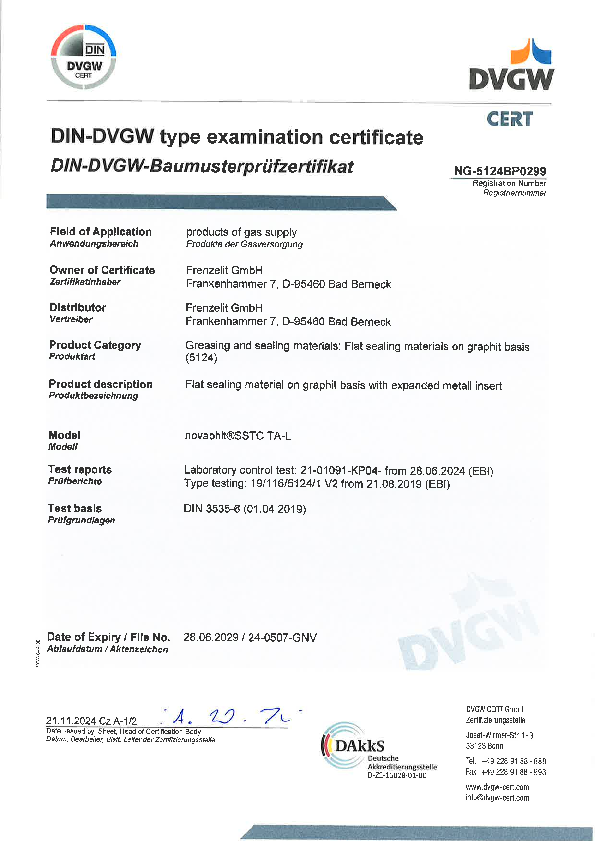

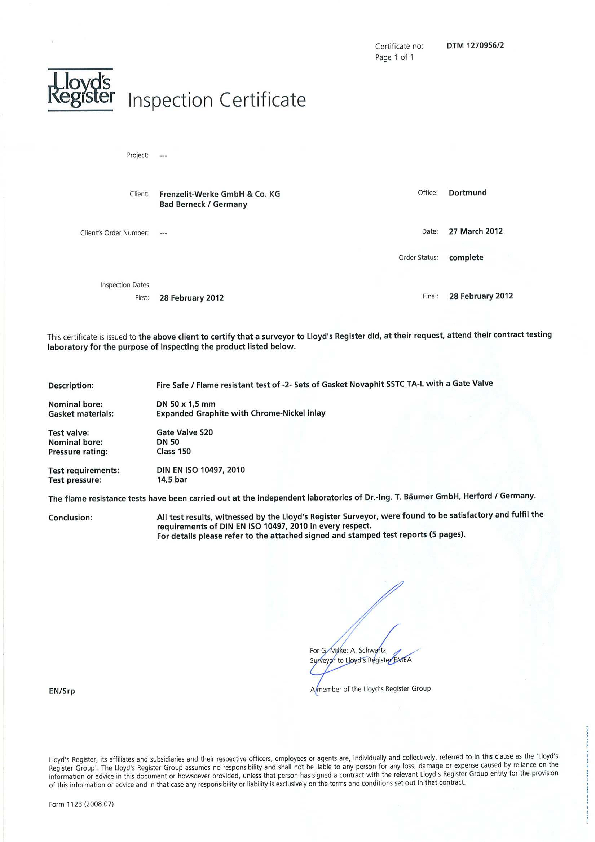

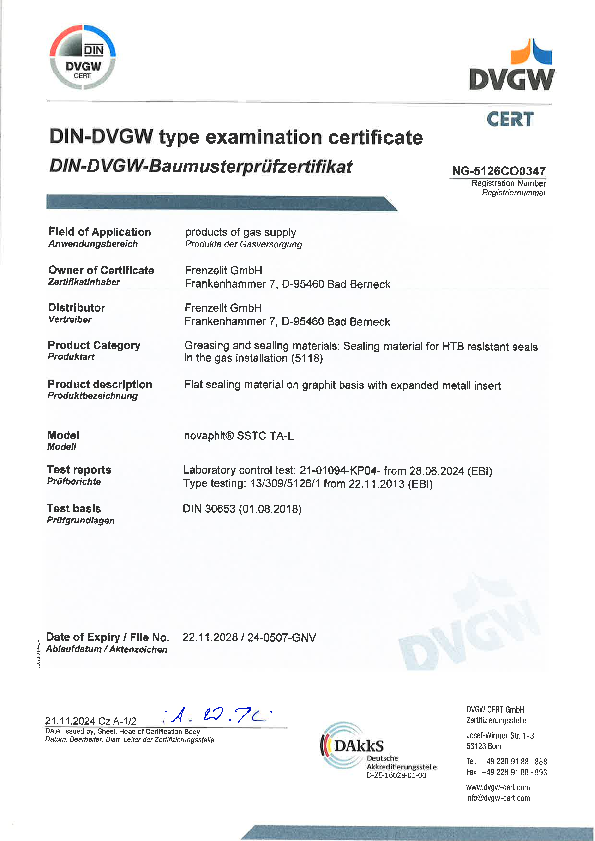

Like novaphit® SSTC, novaphit® SSTCTA-L is made from high-quality expanded graphite with a purity level of at least 99% and has an expanded metal insert made from acid-resistant chrome-nickel steel (1.4404, AISI 316 L). novaphit® SSTCTA-L also has internal impregnation, which reduces the leakage level of the gasket to an even greater degree.

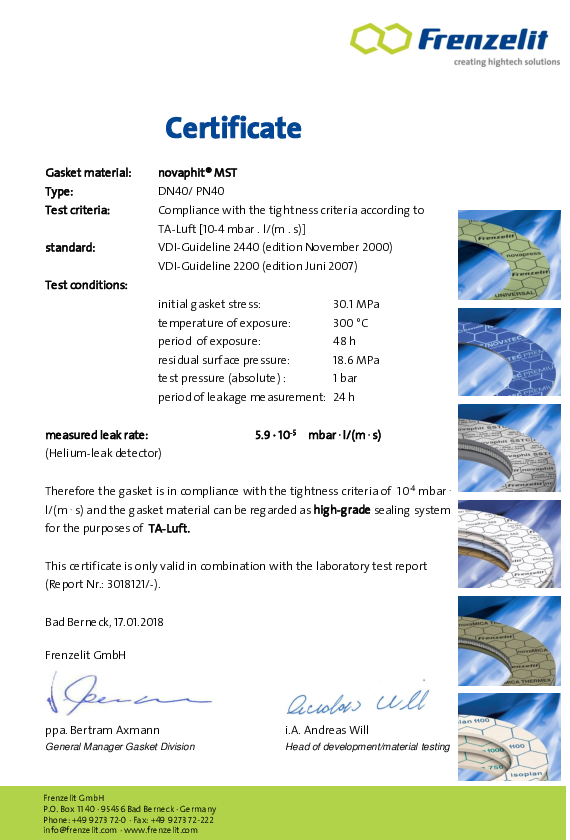

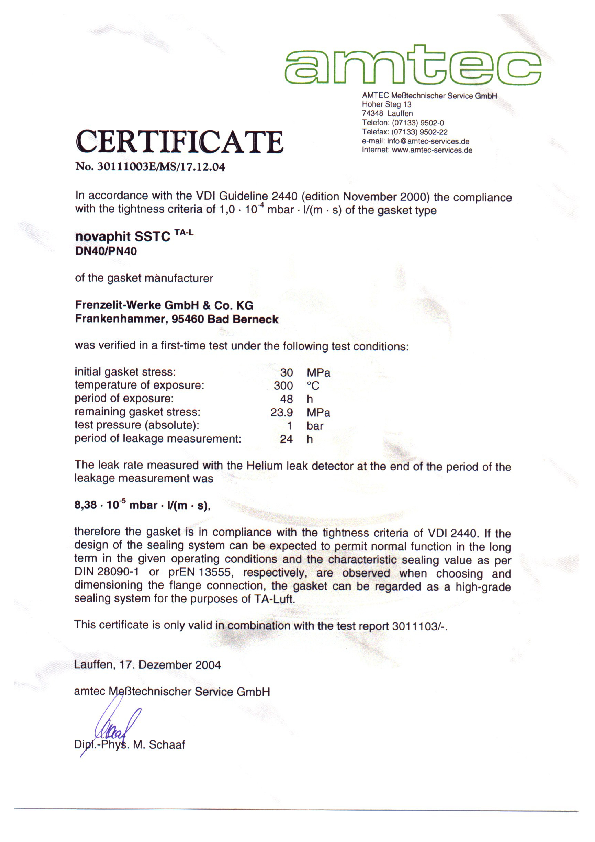

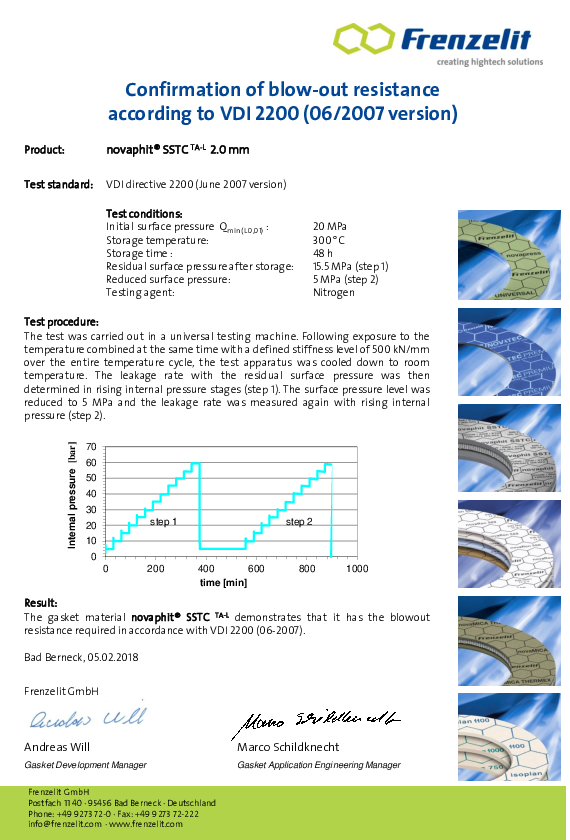

novaphit® SSTCTA-L was tested according to the test criteria of VDI 2440 and/or VDI 2200 for TA Luft. The result: The gasket easily satisfies the TA Luft tightness criterion of 10-4 mbar·l/(s·m) at 30 MPa and/or is below this and is thus considered “high-quality” in terms of TA Luft. The gasket therefore makes a valuable contribution towards environmental protection. Thanks to its superior performance, novaphit® SSTCTA-L makes it possible to produce gasket connections in compliance with the strict criteria of TA Luft and VDI 2290. Comprehensive gasket parameters pursuant to DIN EN 13555 enable effective designs according to DIN EN 1591-1.

novaphit® SSTCTA-L can be used as an all-round standard gasket in a broad range of plant applications and is optionally available with XP technology.

Brochure, technical data sheet and characteristic values

Certifications, approvals and tests:

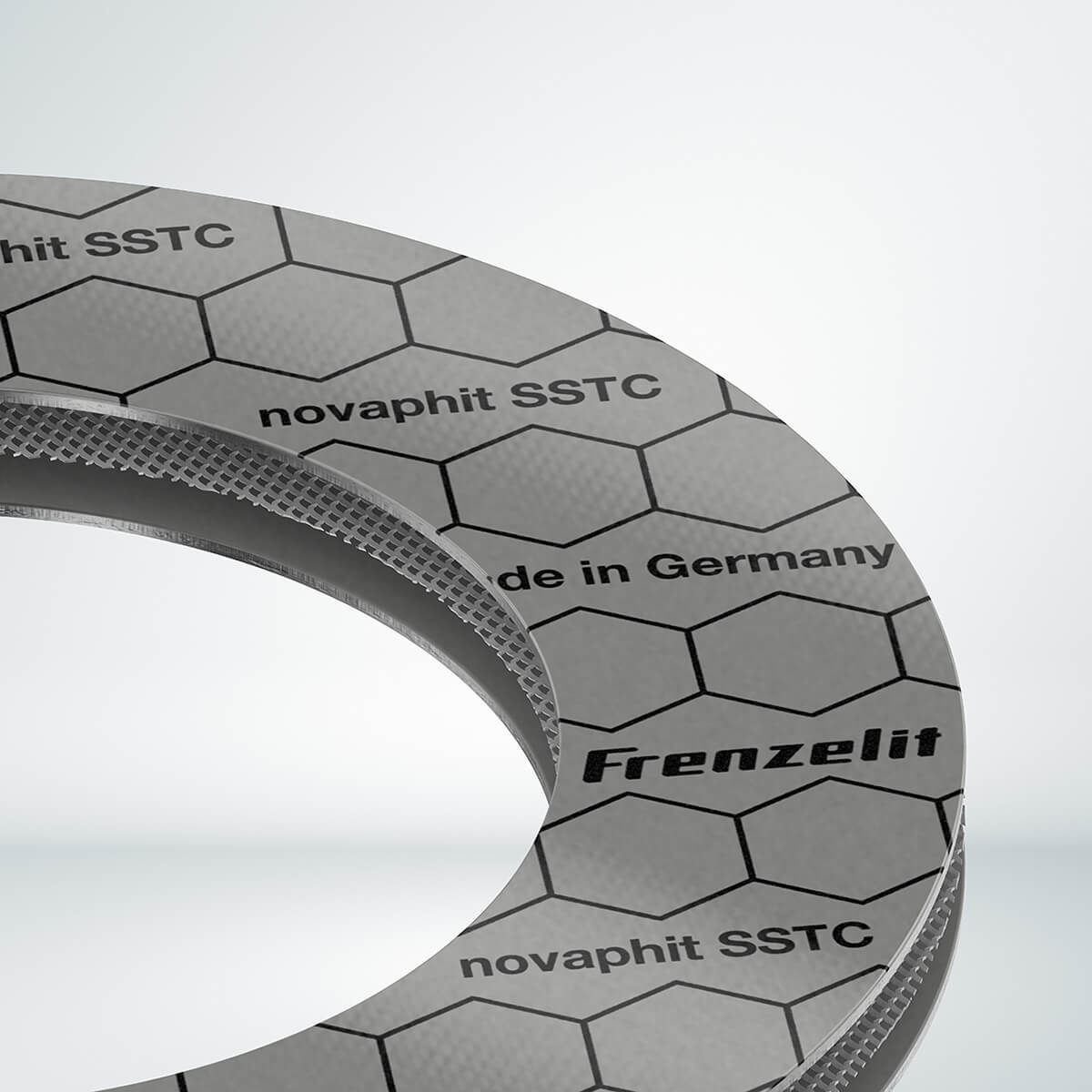

High-quality graphite with intelligent expanded metal insert

novaphit® SSTC is the classic solution of the novaphit® family proven millions of times over. This gasket material made from high-quality expanded graphite (purity: at least 99%) has excellent media resistance and offers maximum reliability with changing loads.

An acid-resistant expanded metal insert (1.4404, AISI 316 L) was specifically chosen as reinforcement for novaphit® SSTC. This delivers superior performance compared to all other commercially available inserts: Thanks to its three-dimensional geometry, it is actively involved in the sealing process and therefore positively influences the gasket’s leakage properties. The combination of high-quality graphite reinforced with an expanded metal insert has a number of advantages:

Optimized surface pressure distribution

Recovery properties optimize the sealing behavior

Favorable grid geometry makes it possible to produce even narrow gasket widths

High fault tolerance in use

Secure handling – even if the material is accidentally bent

novaphit® SSTC can be used as a standard gasket for almost all applications, lowering storage costs and the likelihood of using the wrong gasket. novaphit® SSTC can also be equipped with XP technology on request.

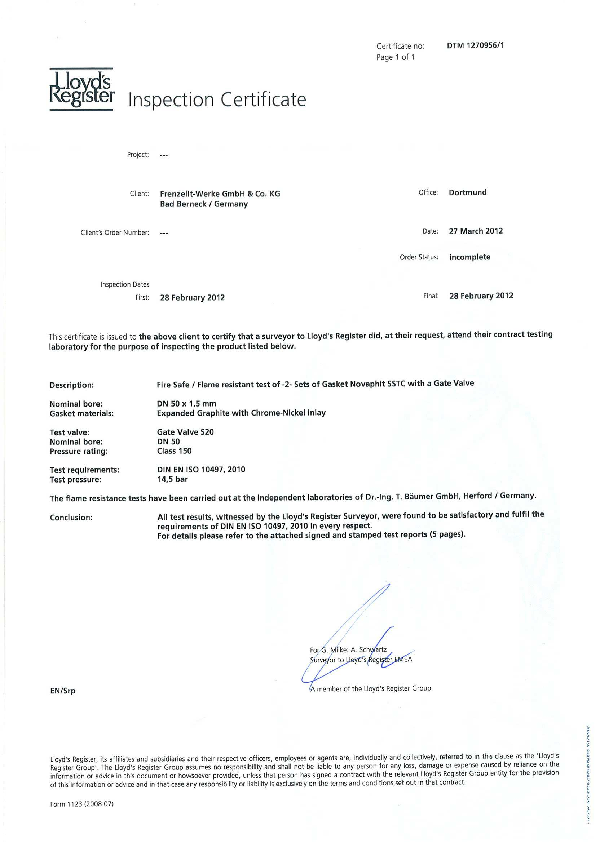

Brochure, technical data sheet and characteristic values

The effective gasket concept for oval closure systems

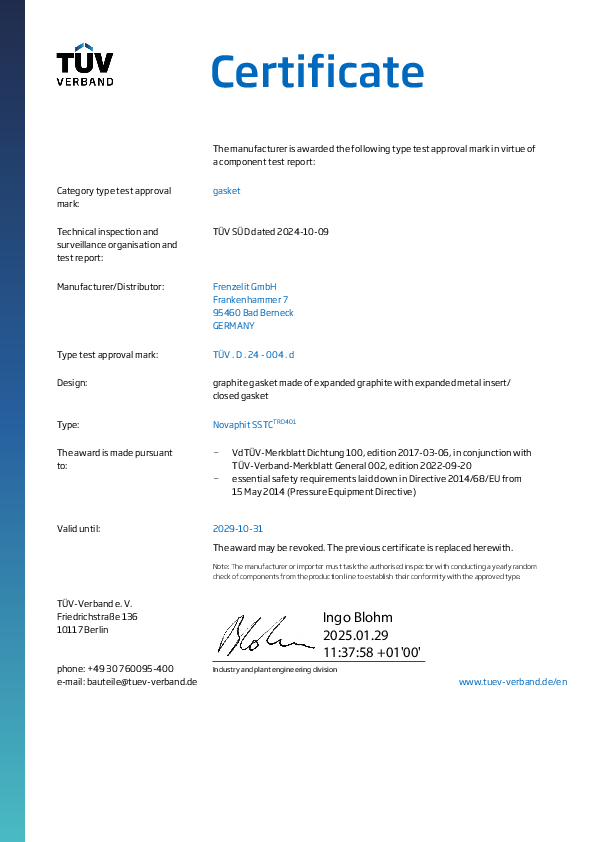

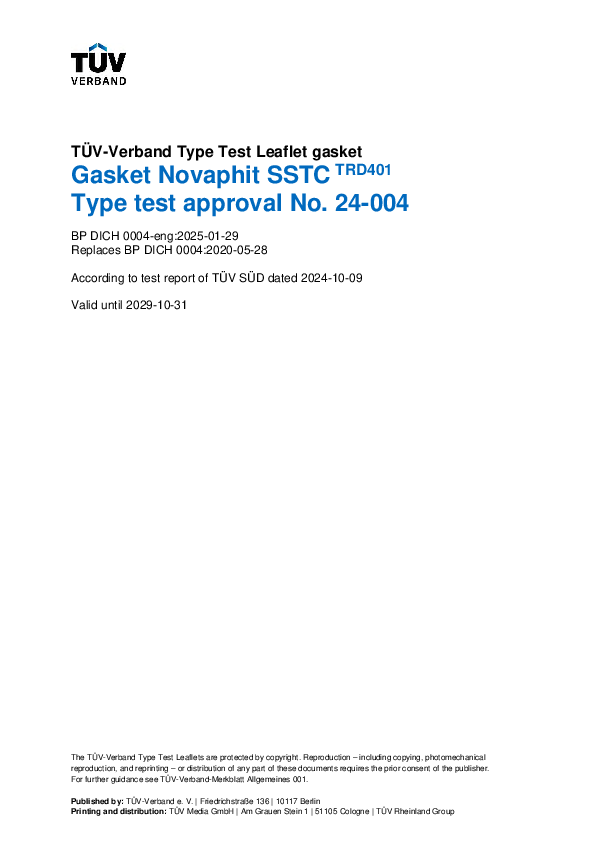

novaphit® SSTCTRD 401 is specifically designed for the production of oval closure lid gaskets for pressure and steam vessels.

Excellent adaptability and recovery properties make this gasket material ideal as a standard material for manhole, headhole and handhole gaskets for steam boilers.

novaphit® SSTCTRD 401 has been tested and approved in the highest test class “d” according to VdTÜV Leaflet “Gasket 100” (previously TRD 401).

novaphit® SSTCTRD 401 can be used for oval closure seals up to 550 °C and approx. 150 bar, depending on the gasket thickness.

novaphit® SSTCTRD 401 can also be equipped with XP technology on request.

Brochure, technical data sheet and characteristic values

Certifications, approvals and tests:

Easy processing thanks to flat metal

novaphit® 400 is the perfect solution for very fine gasket geometries with narrow gasket widths. This effective gasket sheet made from high-quality pure graphite is reinforced with an acid-resistant stainless steel flat metal insert to give it exceptionally good processing characteristics: novaphit® 400 can even be cut to size with a utility knife. Low gasket thicknesses (from 0.5 mm) are also not a problem. This makes novaphit® 400 perfect for many OEM and process industry applications, e.g. in fittings, compressors, pump, valves, etc.

novaphit® 400 is superior to conventional tanged metal gasketsbecause of its flat metal insert optimally embedded in the graphite. It has the following advantages:

Production of thin gaskets (< 1 mm)

Simple production of complex geometries (especially narrow gasket widths)

No risk of injury from burrs that can result from processing

No contact corrosion at the flange surfaces due to projecting metal

No delamination during processing – even with complex geometries

High performance and excellent value

The thicknesses 0.5 and 0.75 mm can optionally be equipped with XP technology.

Brochure, technical data sheet and characteristic values

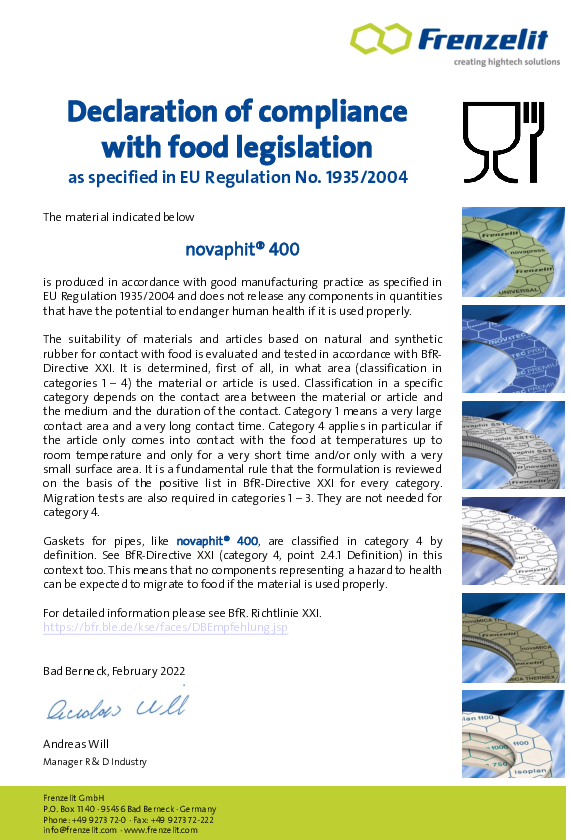

Certifications, approvals and tests:

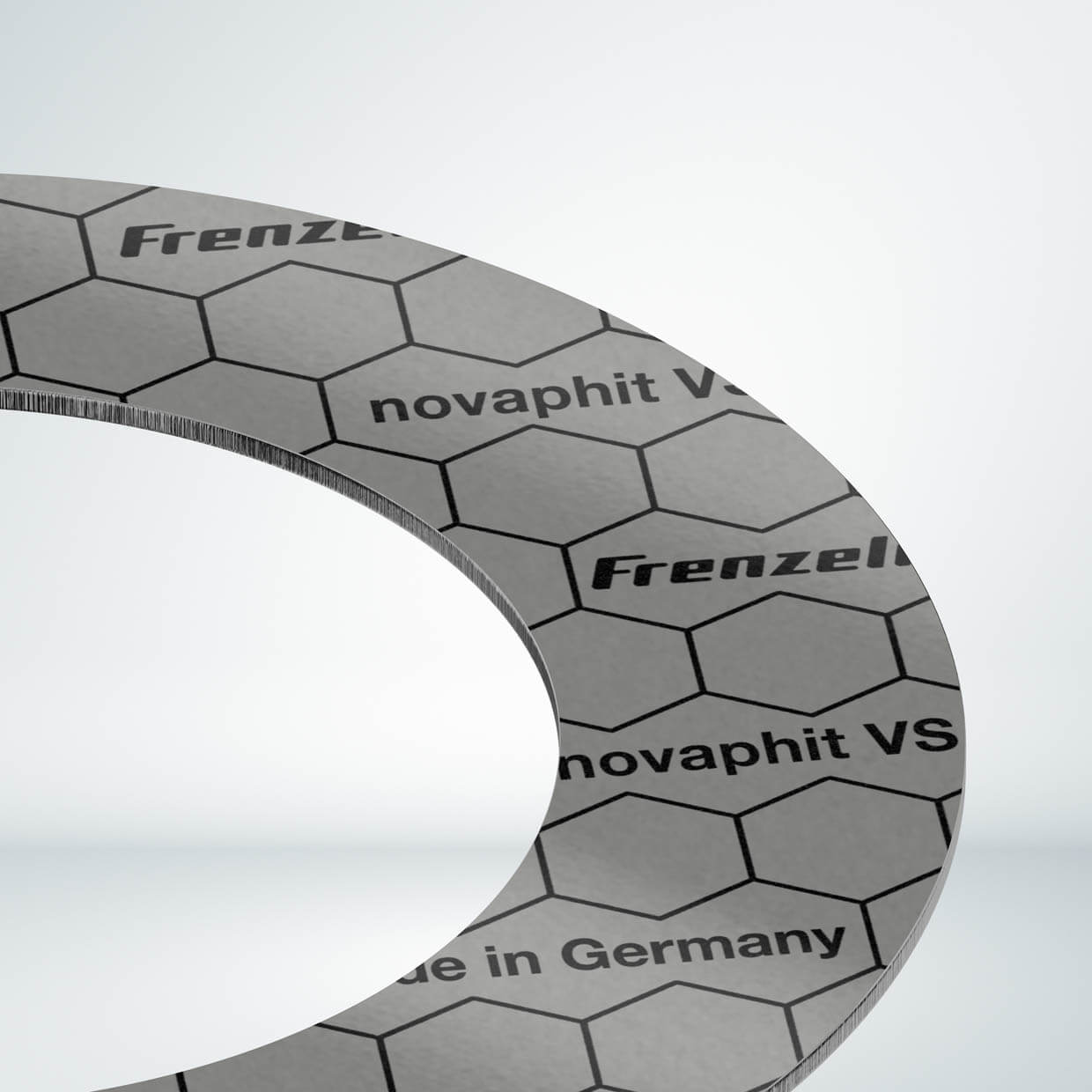

Pre-compressed pure graphite for special requirements

Like all members of the novaphit® family, novaphit® VS consists of high-quality pure graphite with a maximum oxidation loss of 4 %/h (limit value according to standard DIN 28091-4 for expanded graphite-based gasket materials), but it does not contain a reinforcing insert. This is a good option when the use of a metal insert is not possible for chemical reasons, e.g. with extremely aggressive media.

Since there is no insert it is especially easy to realize thin gaskets or complex geometries. novaphit® VS is already slightly pre-compressed in the production process to optimize the handling properties.

novaphit® VS can also be equipped with XP technology if required.

Brochure, technical data sheet and characteristic values

Ultra-pure graphite sheet in standard density of 1.0 g/cm³

novaphit® M is a high-quality pure graphite sheet with a standard bulk density of approx. 1.0 g/cm3. The material can be used, e.g. for manufacturing of conventional flat gaskets that must withstand application temperatures up to 550°C.

To achieve even higher performance, novaphit® M can be equipped with XP technology on request.

Brochure, technical data sheet and characteristic values

Tapes made from graphite foil wound on a reel

novaphit® M REEL is a 0.5 mm thick high-quality foil made of expanded graphite that can be cut into different widths and is wound onto a reel. This format makes the material ideally suited as a soft layer for semi-metallic gaskets and filling material for spiral wound gaskets. Furthermore, tapes of novaphit® M REEL can also be used, e.g. for the manufacturing of graphite bearings.

novaphit® M REEL is perfectly suited for temperatures up to 550°C.