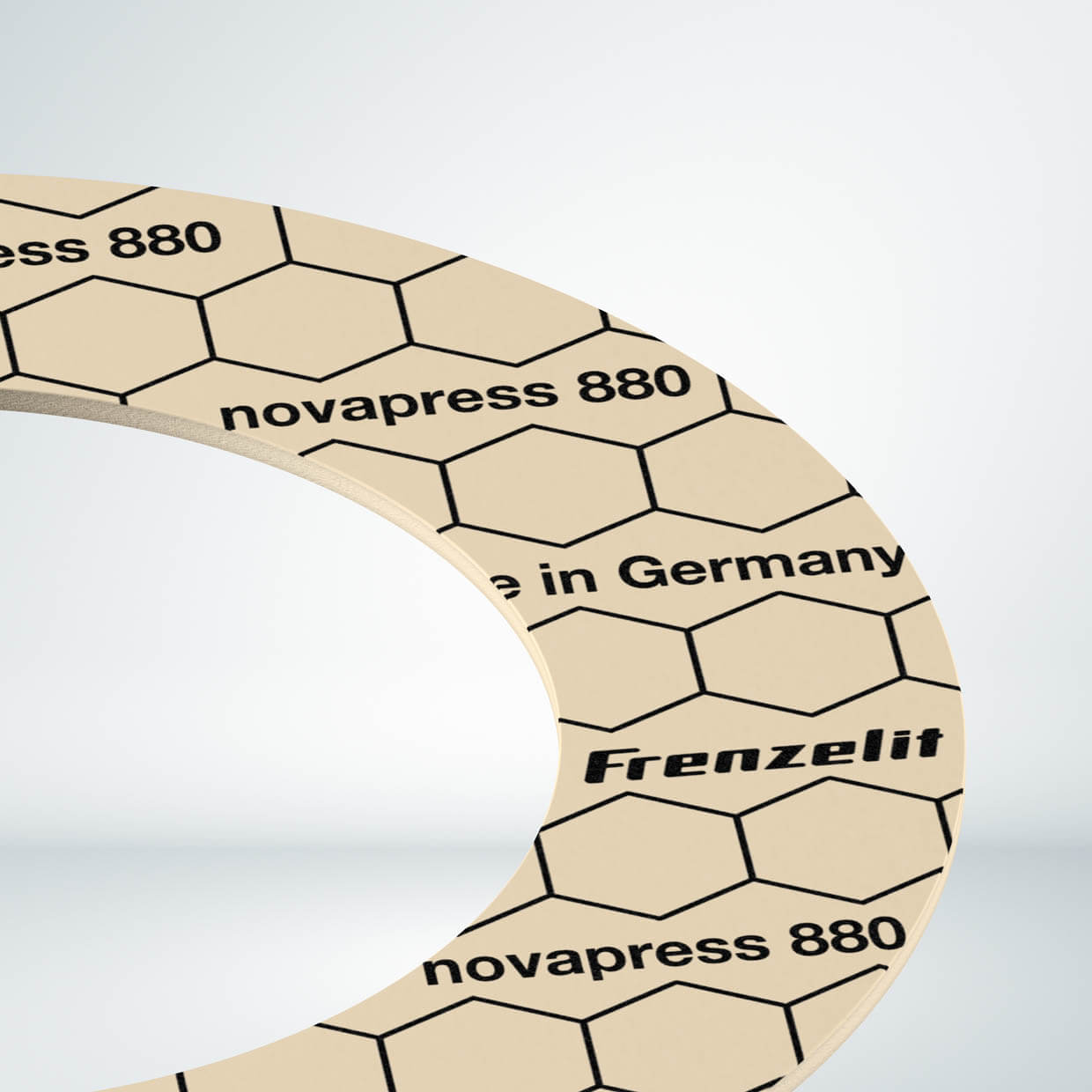

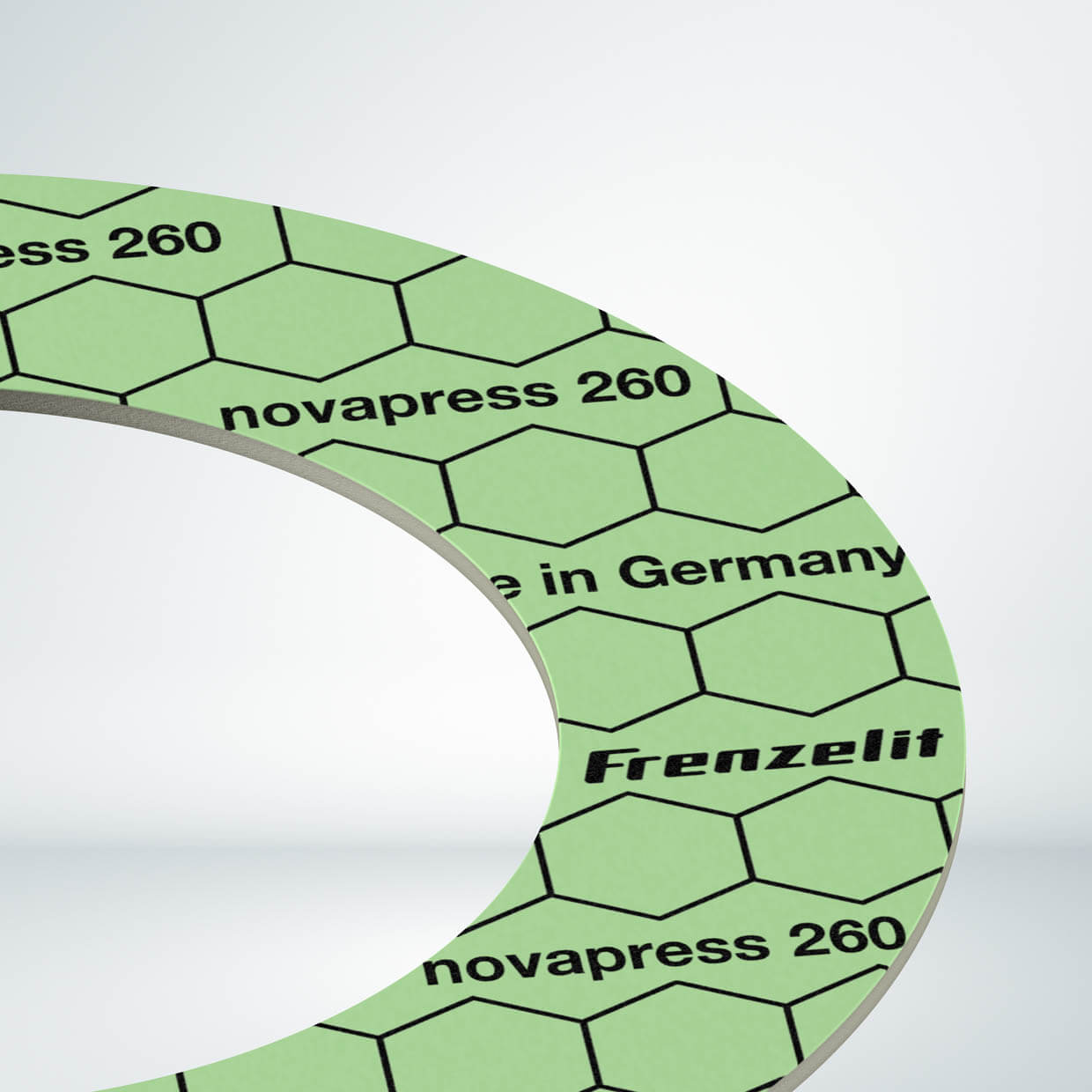

novapress®

Elastomer-bonded fiber gaskets

Future-oriented fiber gaskets

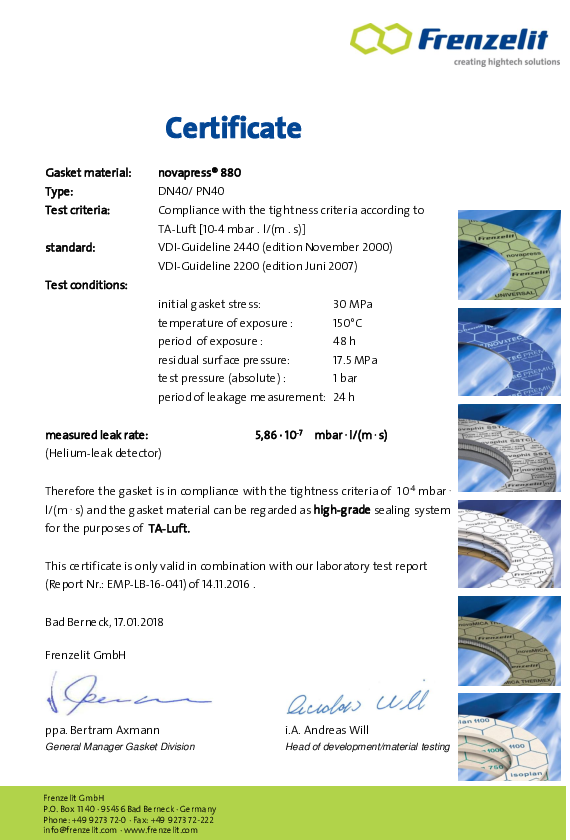

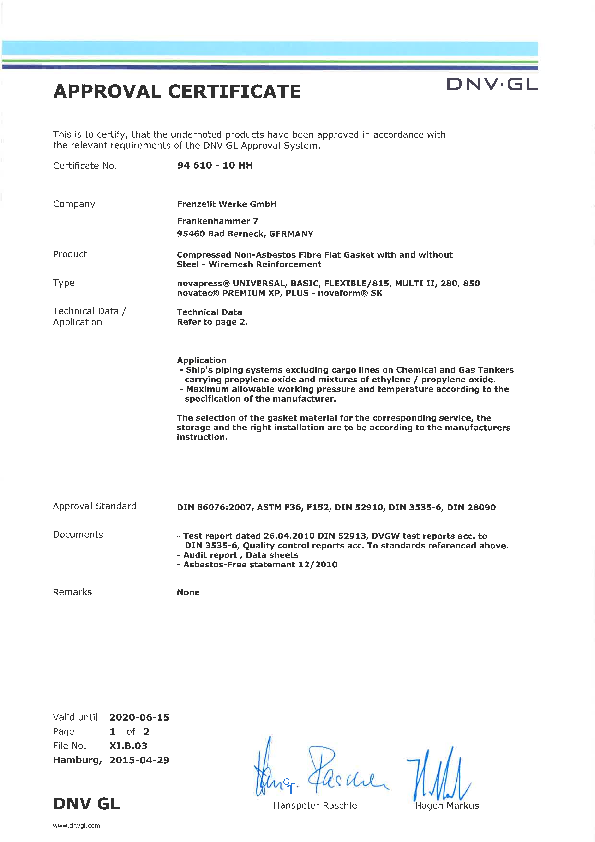

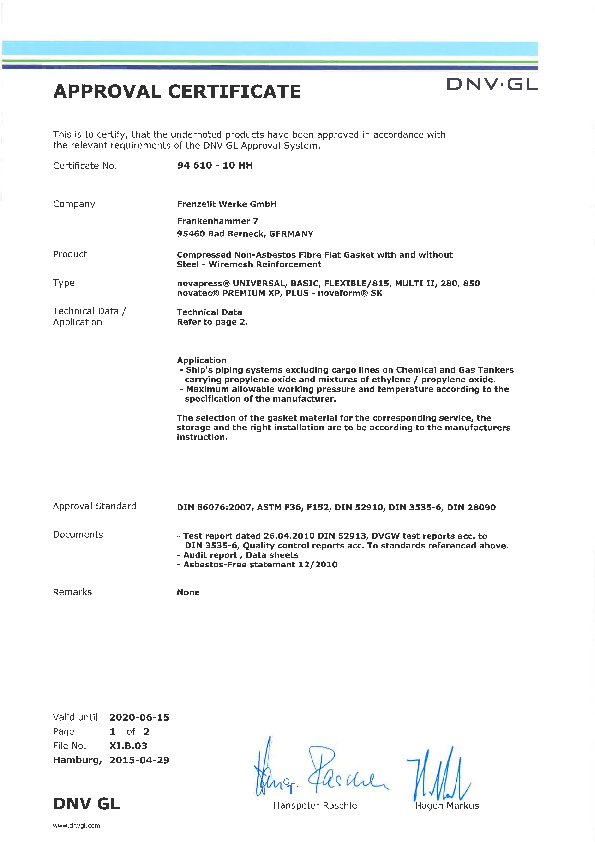

The novapress® product family represents the latest technology in fiber-based gasket sheets. The use of the latest process technology and a process control system for the entire manufacturing process guarantees consistent quality at the highest level – made in Germany.

novapress® is a group of elastomer-bonded gasket materials based on high-quality aramid fibers and special functional fillers. novapress® products are the standard in flat gasket applications and cover nearly all conventional applications; however, each product has special properties that make it ideal for use in specific applications.

Whether it’s innovative materials or gasket solutions that have been used successfully for many years – the novapress® product line offers you the right gasket material for countless applications.

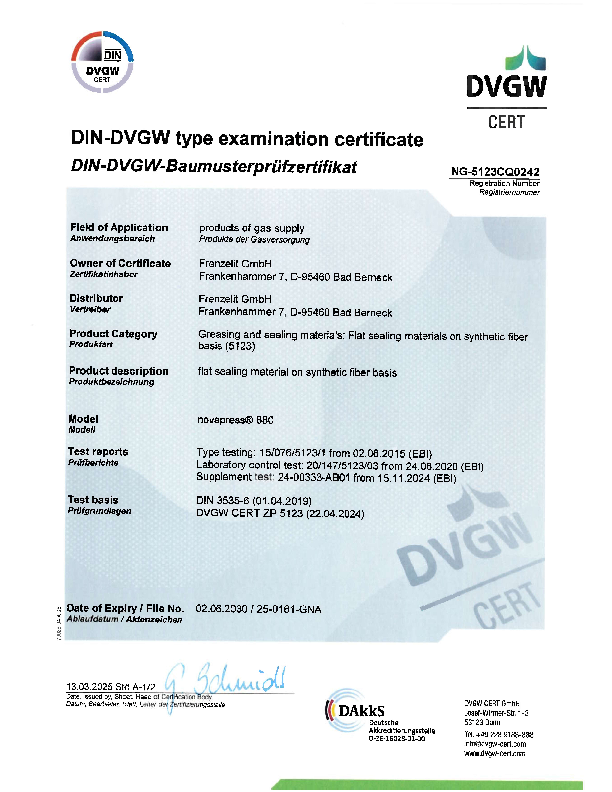

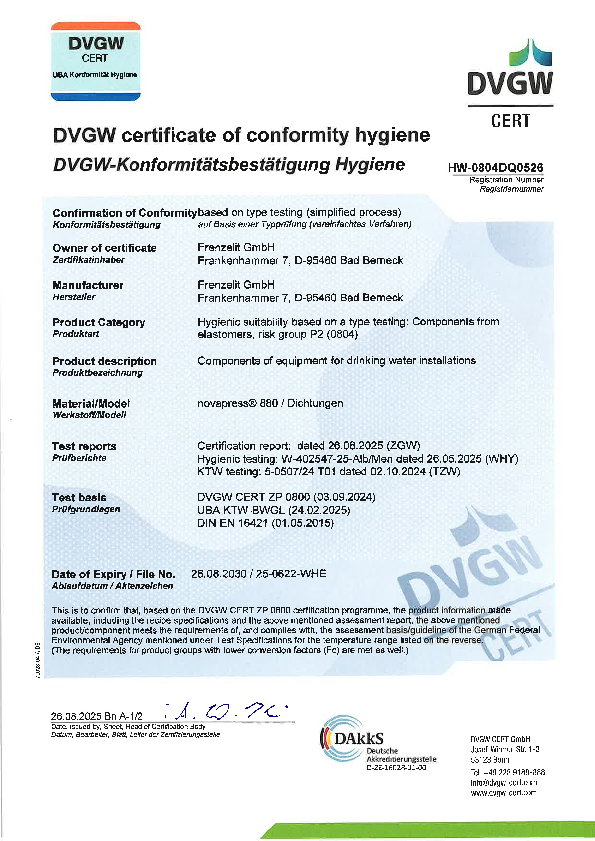

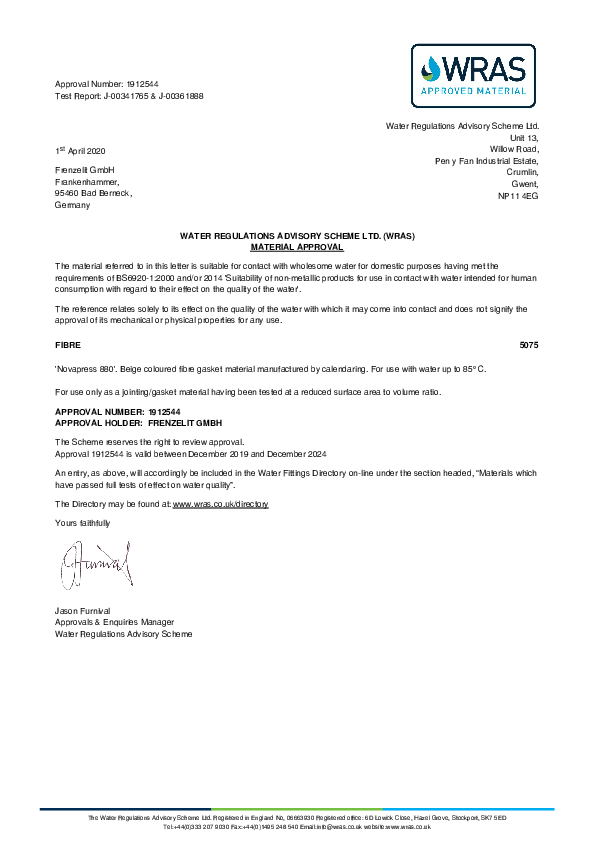

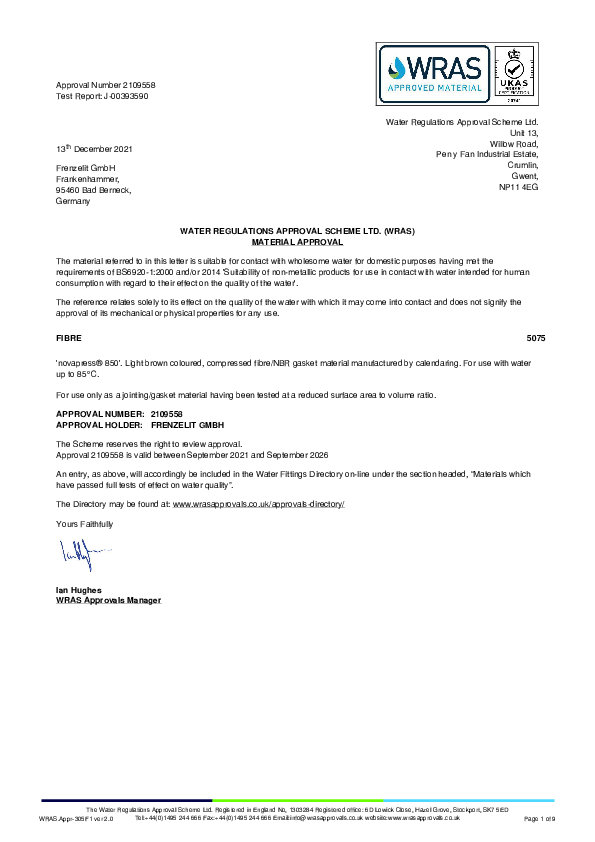

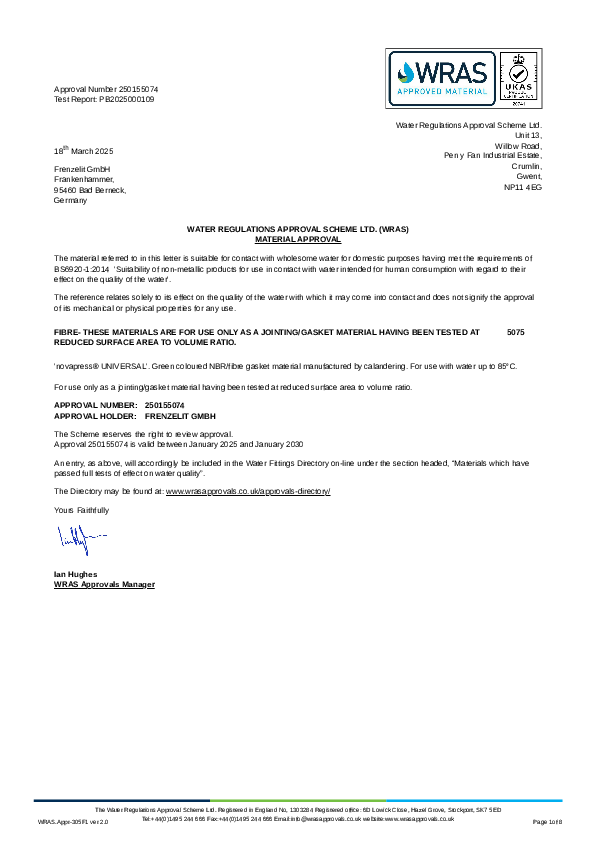

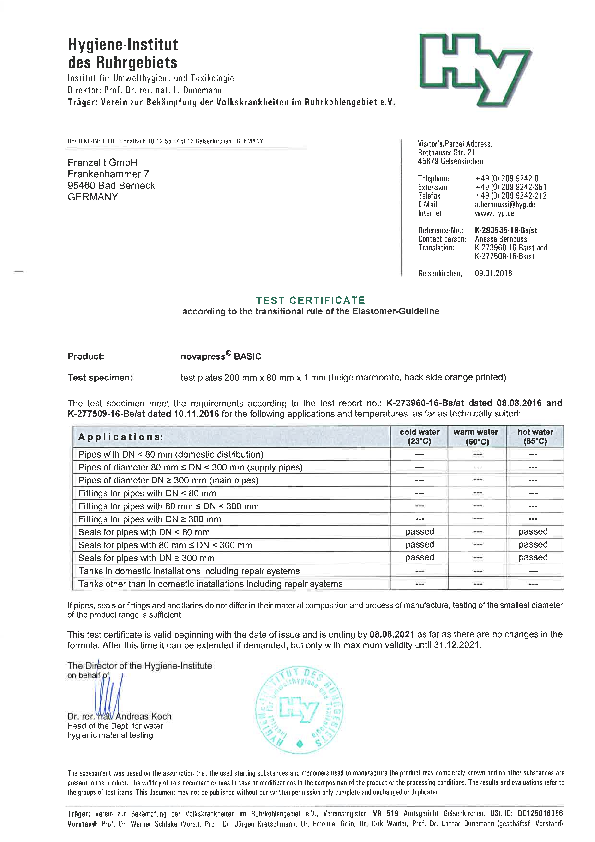

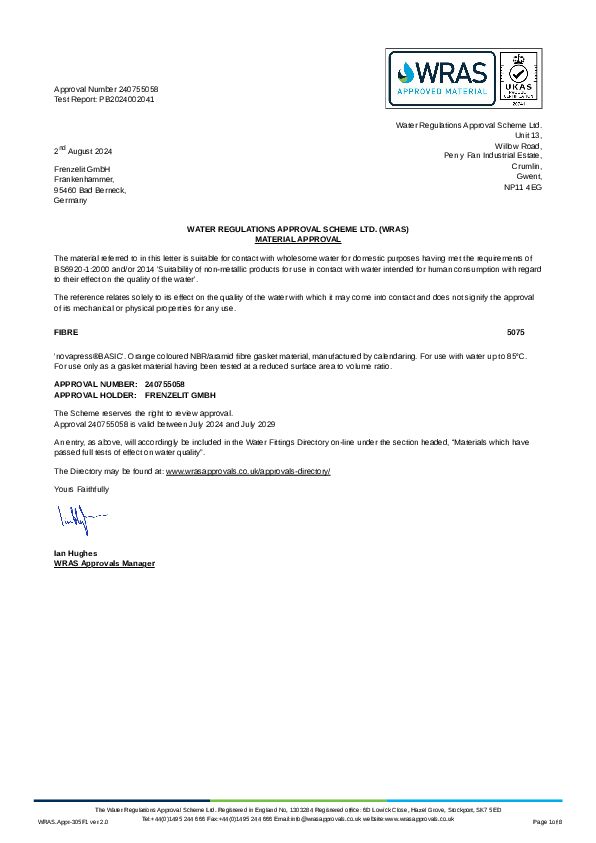

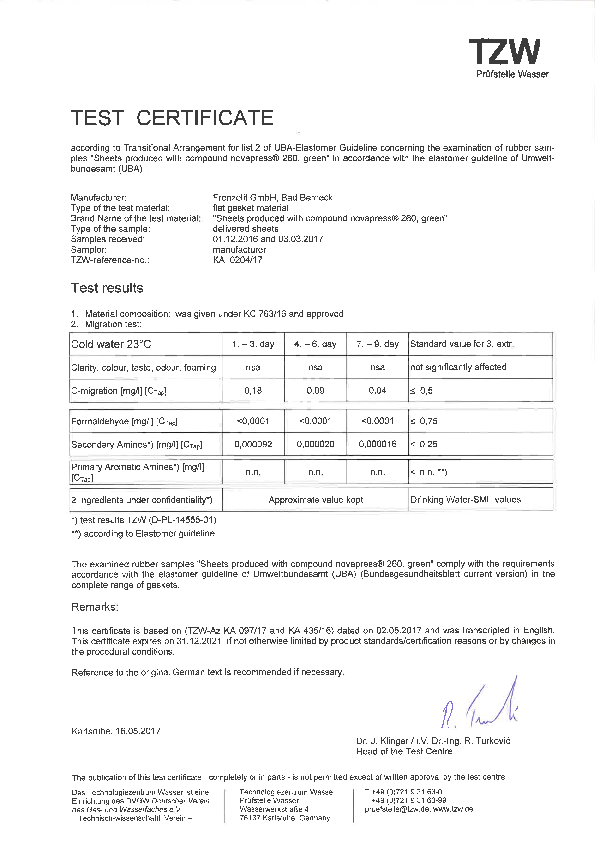

Elastomer Guideline - Transfer to KTW - BWGL

The validity of the elastomer guideline expires at the end of 2021. From 01 January 2022, the Elastomer Guideline (ELL) will be integrated into the KTW BWGL (Plastics in Drinking Water - Basis for Assessment) as Annex D. For the mandatory validity to meet the requirements according to the KTW BWGL, a transition period of 2 years is foreseen, i.e. until the end of 2023. Within these 2 years, test reports according to the previous elastomer guideline (and W270) may still be used to prove suitability.

Learn more:

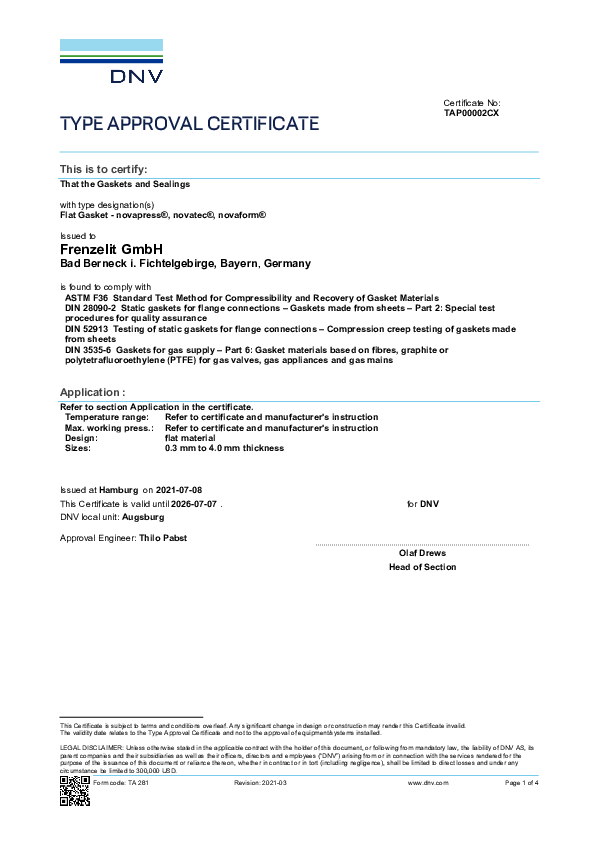

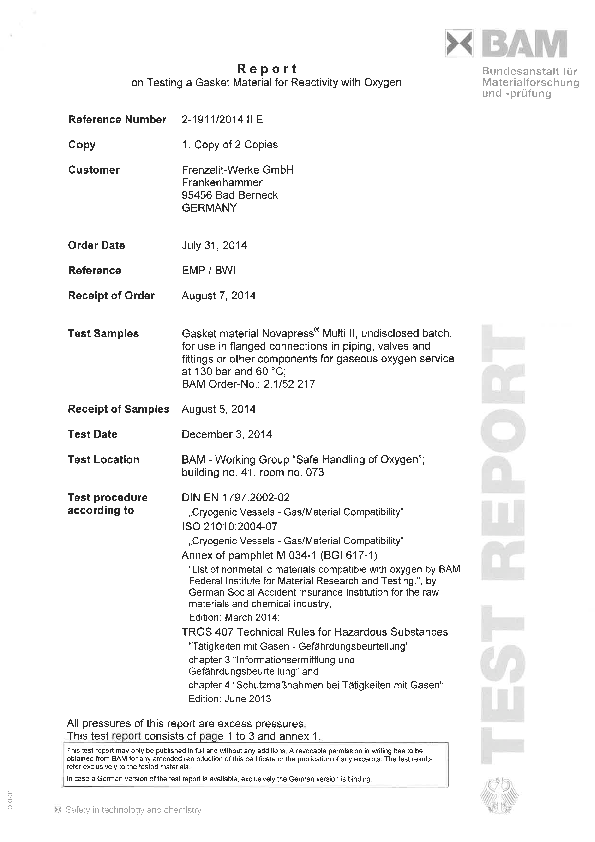

Future applications with hydrogen

In the future, Frenzelit will mark products suitable for hydrogen applications with a registered H2 - logo. Materials and products marked as "H2 - approved" have been tested in both resistance and leakage tests with the medium hydrogen and their suitability has been proven.