novaform®

Gaskets

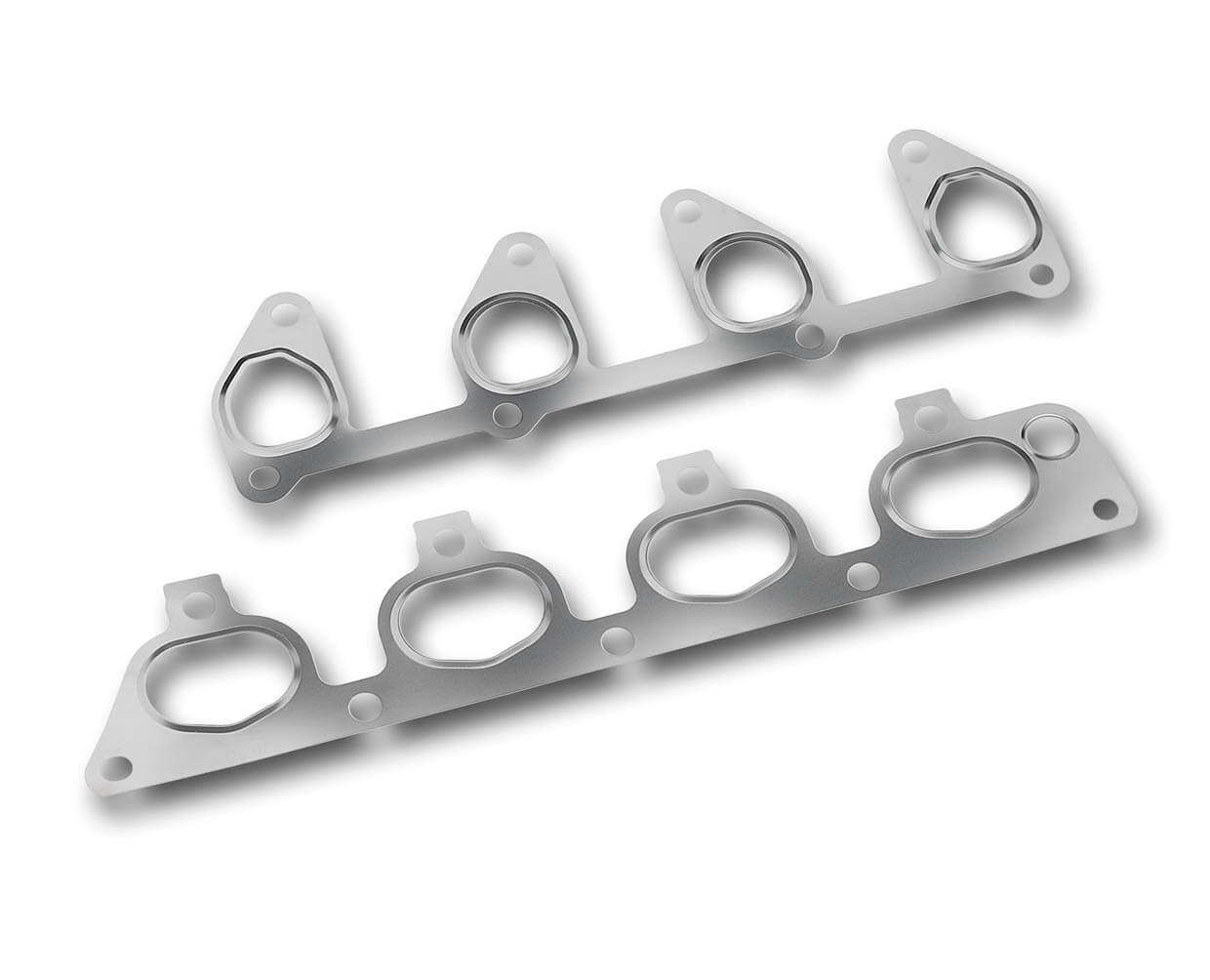

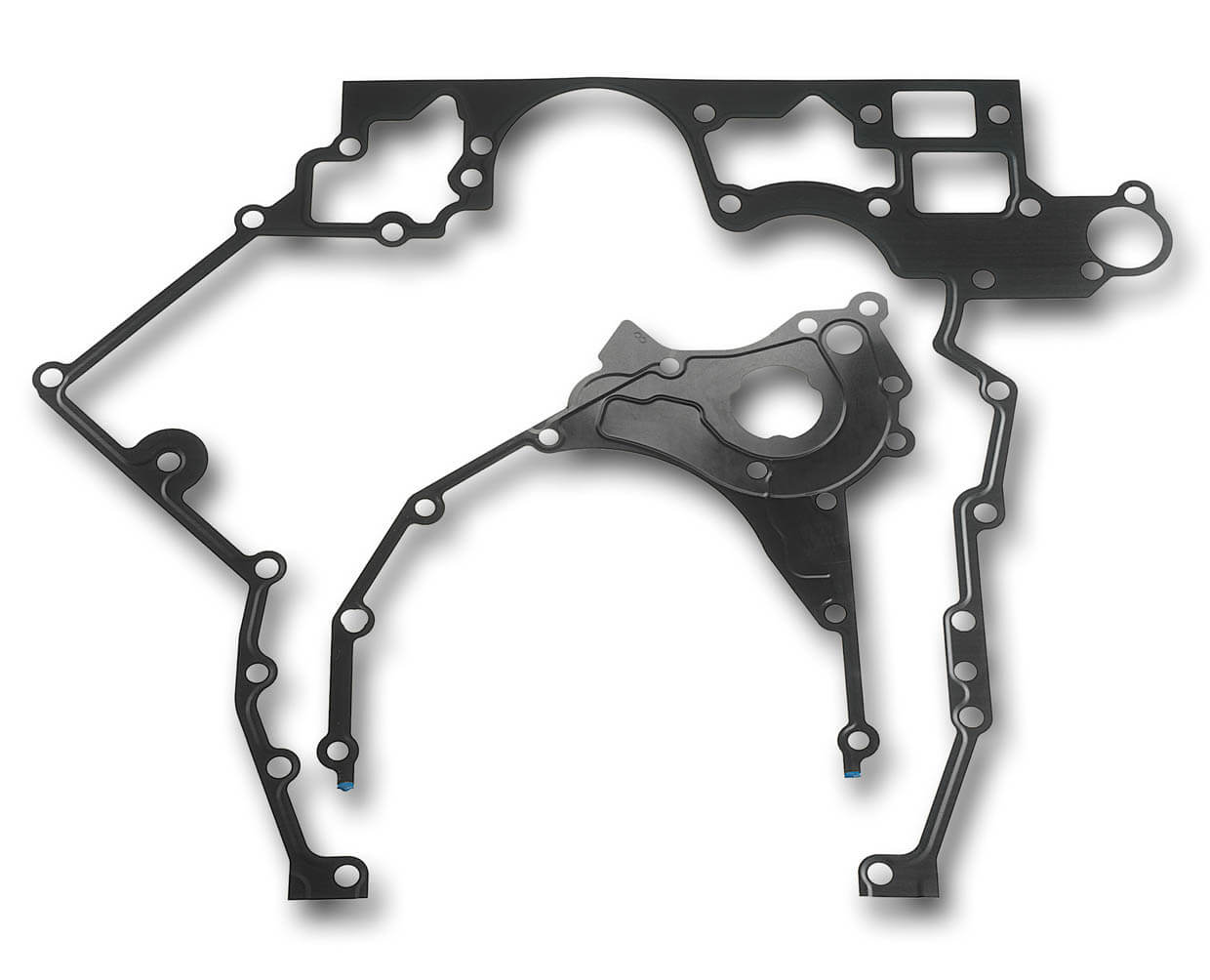

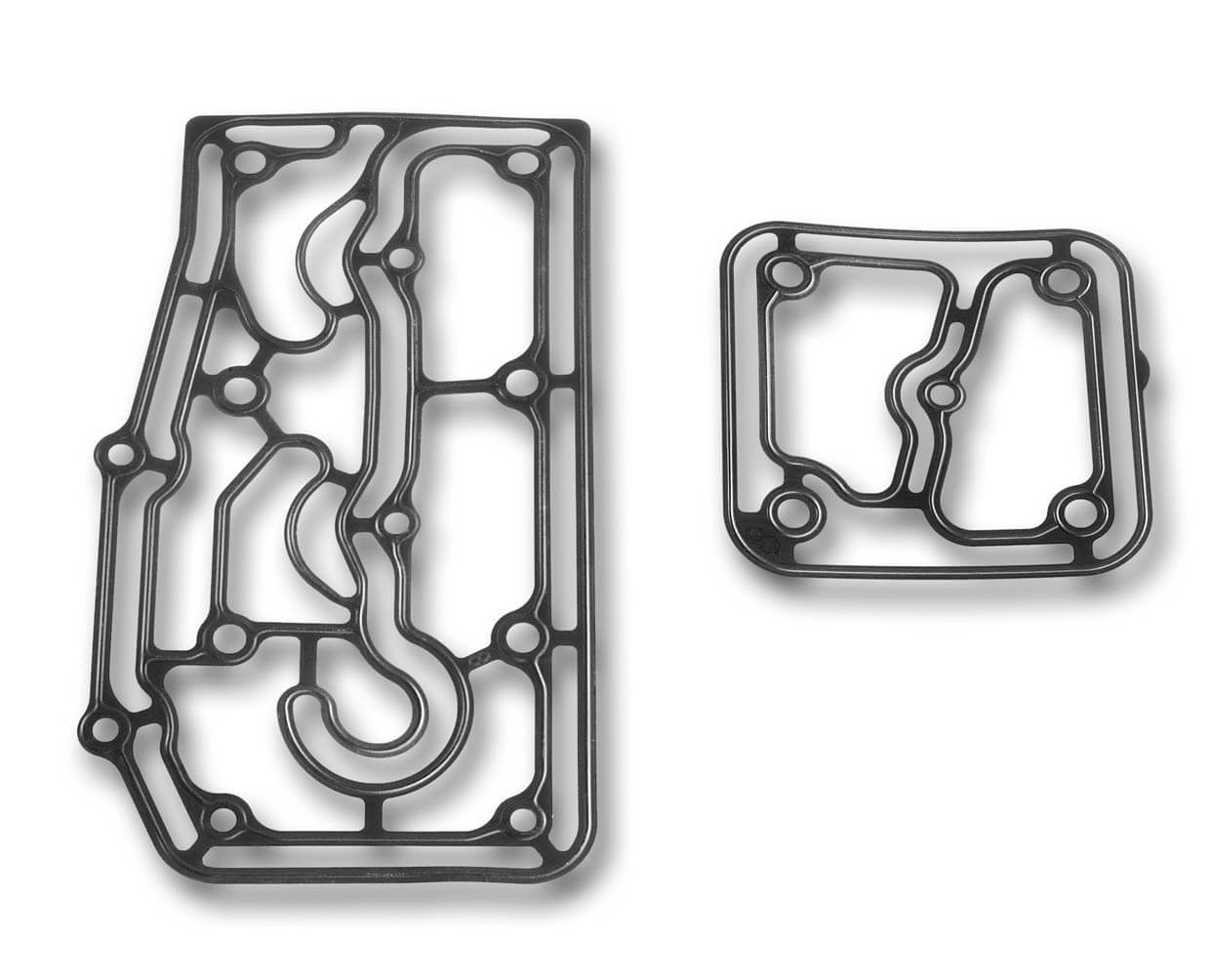

novaform® GB

Metal bead gaskets

Metal bead gaskets

Material profile

Sheets coated with elastomers in the coil process or bright metal sheets are processed into high-quality metal bead gaskets using the progressive die method.

- For narrow gasket widths

- Even with low surface pressure

- Practically no setting – creates a permanent seal

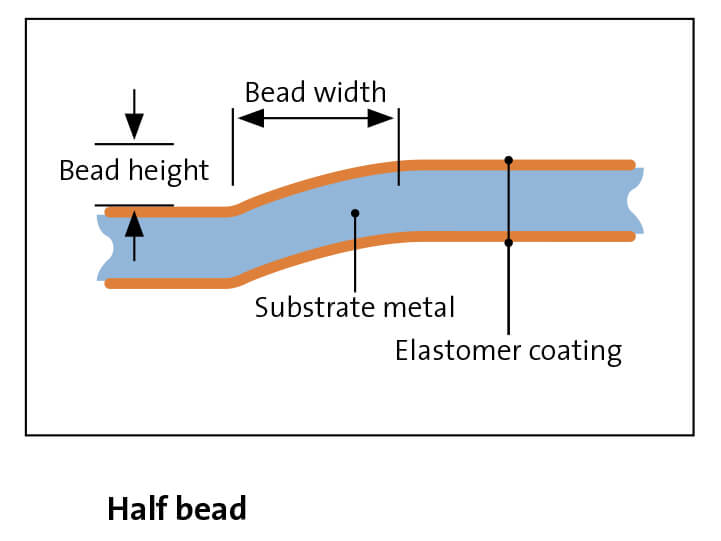

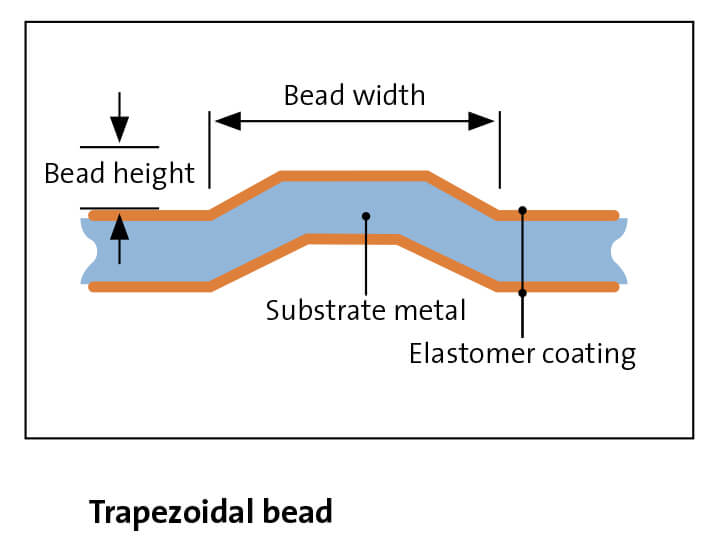

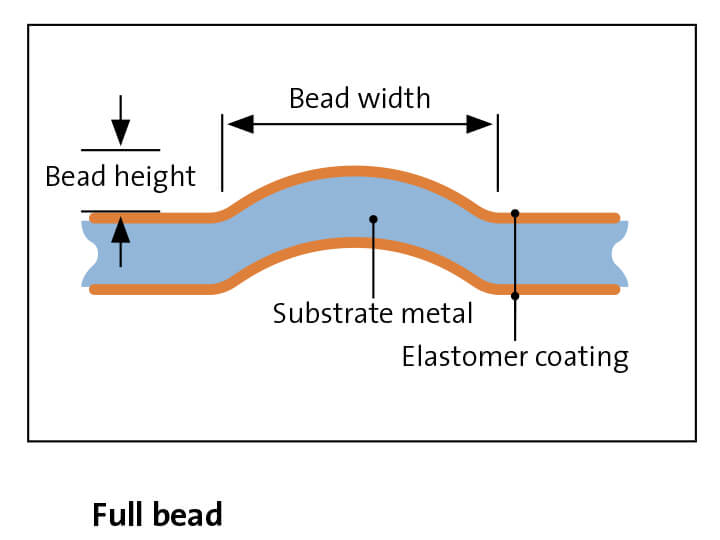

Macro adjustment to the sealing surfaces takes place by means of preformed beads in novaform® GB. Micro range sealing additionally occurs through a special elastomer coating applied to the metal substrate. This combination of different materials guarantees that the joint is permanently tight – also with extremely low connecting forces – even if the sealing point is subject to extreme temperatures or frequently changing loads.

Other non-ferrous metals such as copper possible on request.