Hydrogen – a key element in the transition to renewables

There is no avoiding hydrogen in the future: For emission-free power generation, as an environmentally-friendly drive for utility vehicles and aircraft or as an industrial fuel

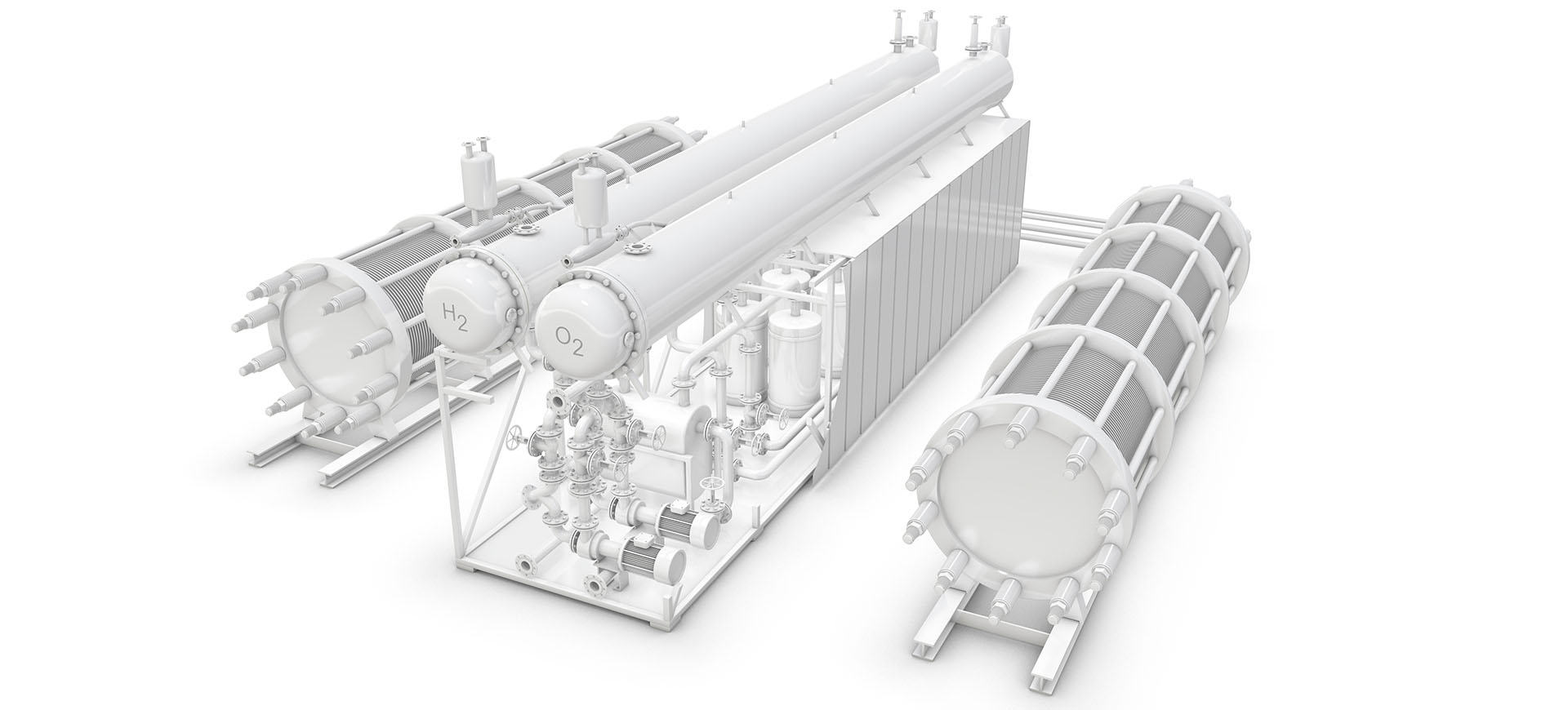

Generating hydrogen – electrolysis

Water is converted into its elements hydrogen and oxygen with the help of energy. If the energy originates from renewable sources, the resulting “green” hydrogen is a CO2-free energy source.

Hydrogen is produced in electrolyzers. Various electrolytes and temperatures can be used, depending on the method. Irrespective of the method, smooth and efficient operation requires good sealing of the important system components: The discharge lines for hydrogen and oxygen, and the individual electrolysis cells that are connected in series in a stack structure within the electrolyzer. Tank systems, conveying lines and fittings also require “hydrogen-compatible” and reliable gasket materials.

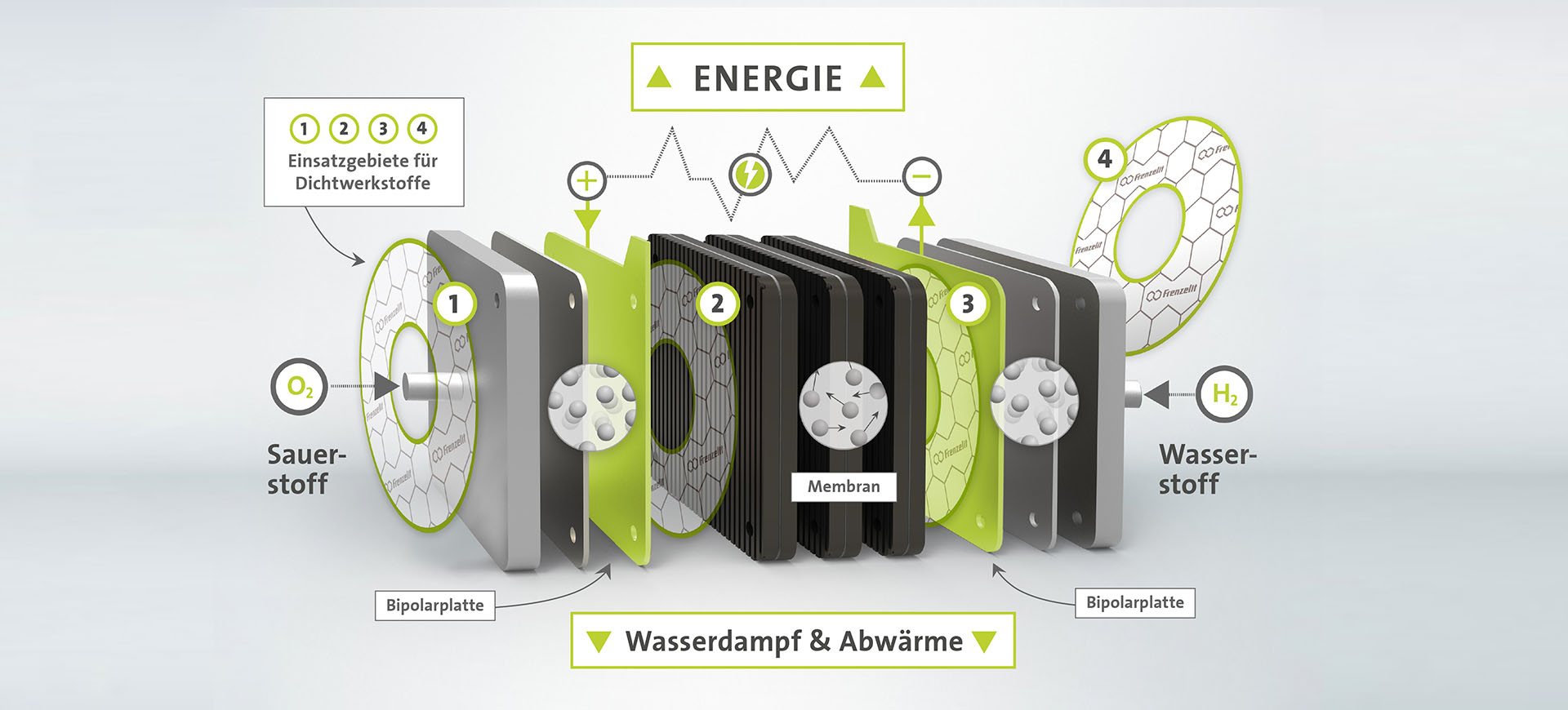

The fuel cell – power generation based on hydrogen

A fuel cell generates electrical energy and heat from hydrogen and oxygen – and the only “waste” product is water.

A single fuel cell consists of two electrodes (anode and cathode) with bipolar plates that distribute the fuels hydrogen and oxygen, and that transport the electricity away. A specific electrolyte is added to the cell. However, a single fuel cell generates only a small amount of electricity, so, in practice, cells are connected in series to form a stack.

Material competence: Gasket materials inside the cell

The less gas escapes, the greater the efficiency of the fuel cell. Good sealing is therefore decisive. Frenzelit uses its material and production expertise from numerous projects to offer gaskets that have the precise properties that are needed in the respective areas.

Numbers in the graphic: 1, 4:

Gaskets for the hydrogen and oxygen supply lines – both gases are combustible, potentially explosive and difficult to handle. The right gasket ensures the necessary safety in this case.

Numbers in the graphic: 2, 3:

Gaskets between the stacks prevent the combustible gases and electrolytes from escaping, shield the bipolar plates from each other and prevent short circuits.

Find out more about the gasket materials for fuel cells in our case study

Innovation for the gas diffusion layer

The gas diffusion layer (GDL) is the decisive component for the optimal transport of the reaction gases H2 and O2 to the electrodes and the efficient discharge of the reaction products electricity and water. The innovative carbon fiber nonwoven hicoTEC® NE by Frenzelit is perfectly suited for this task.

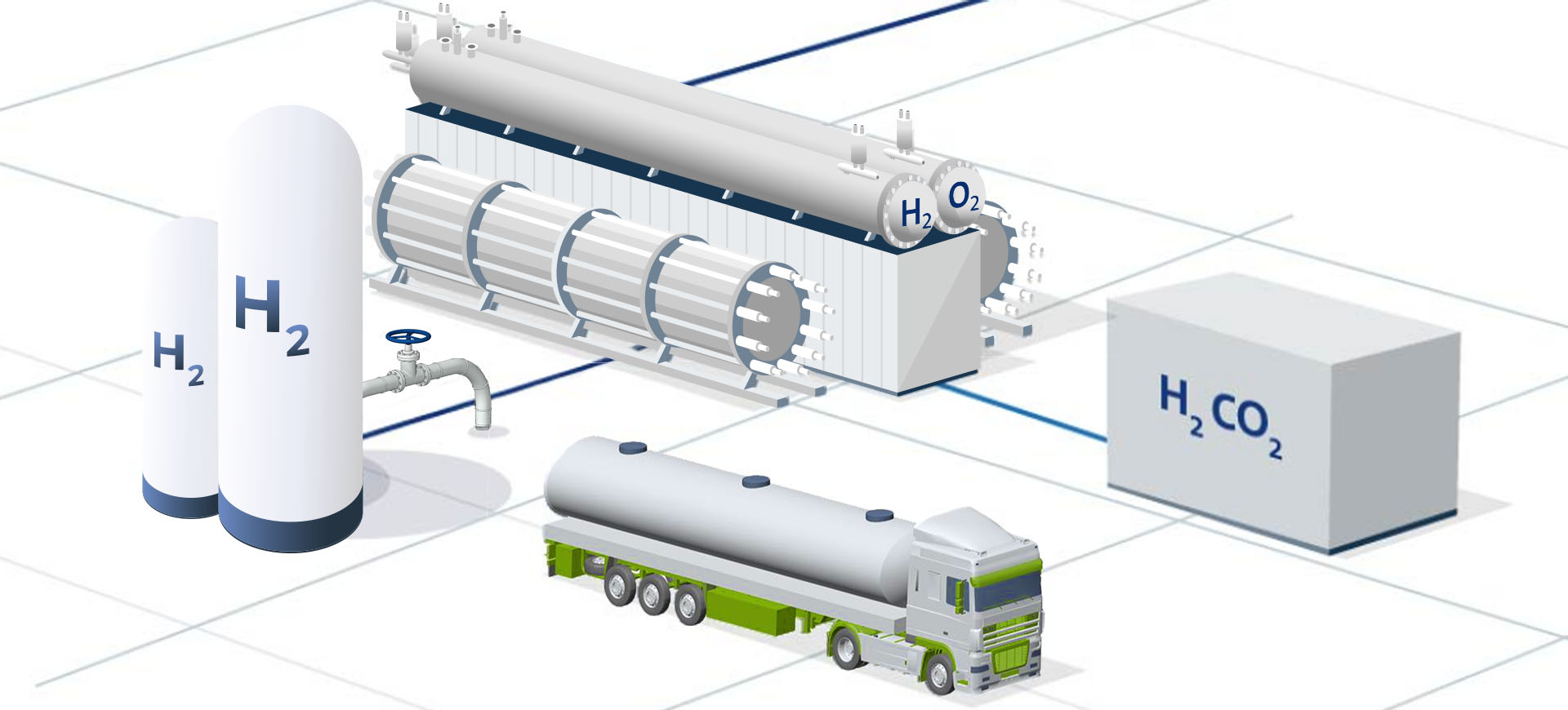

Power-to-X

Conversion of excess green electricity is not always about storage and utilization of the “pure hydrogen”. In various Power-to-X scenarios, hydrogen is used as the raw material to produce other chemical energy carriers. Numerous processes are used, for instance, to produce methane, e-fuels (power-based synthetic diesel and gasoline, and kerosene for aircraft) or ammonia as an important base material for the chemical industry.

A proven partner for chemical process plants

Generation and distribution of raw materials should be as efficient and loss-free as possible in each plant. The essential basic requirements: The proper sealing and insulation of fittings, conveying lines and tank systems. Frenzelit offers the most suitable products based on our decades of industry expertise.

Distribution of hydrogen

Hydrogen can be transported over long distances in existing gas networks. However, hydrogen poses major challenges for the gaskets in the pipe systems, tanks and fittings. It is an extremely combustible and potentially explosive gas; technical safety aspects therefore play a major role.

These special tightness requirements for hydrogen also equally apply to the transport of hydrogen containers by rail, road or ship.

As there are practically no official standards for gasket materials in hydrogen applications, Frenzelit carries out their own tests for sealing performance verification. You can rely on hydrogen-compatible Frenzelit products. As indicated by our test seal.