isoplan® GREENLINE

Innovative, eco-friendly insulation materials

isoplan® GREENLINE product family is a generation of innovative, eco-friendly insulation materials based on biosoluble fibers that are not classified according CLP and REACH.

Easy to process and shape

isoplan® is easy and quick to process – even directly on site – with all standard cutting tools. When moistened it can also be shaped as required and it retains the shape after it has dried. In addition, the material can also be glued at the ends or with other surfaces. You can even lay multiple isoplan® boards on top of each other or glue them together to achieve an even higher material thickness and greater insulation effect. Frenzelit offers a special high-temperature-resistant adhesive for this purpose. Ask about it!

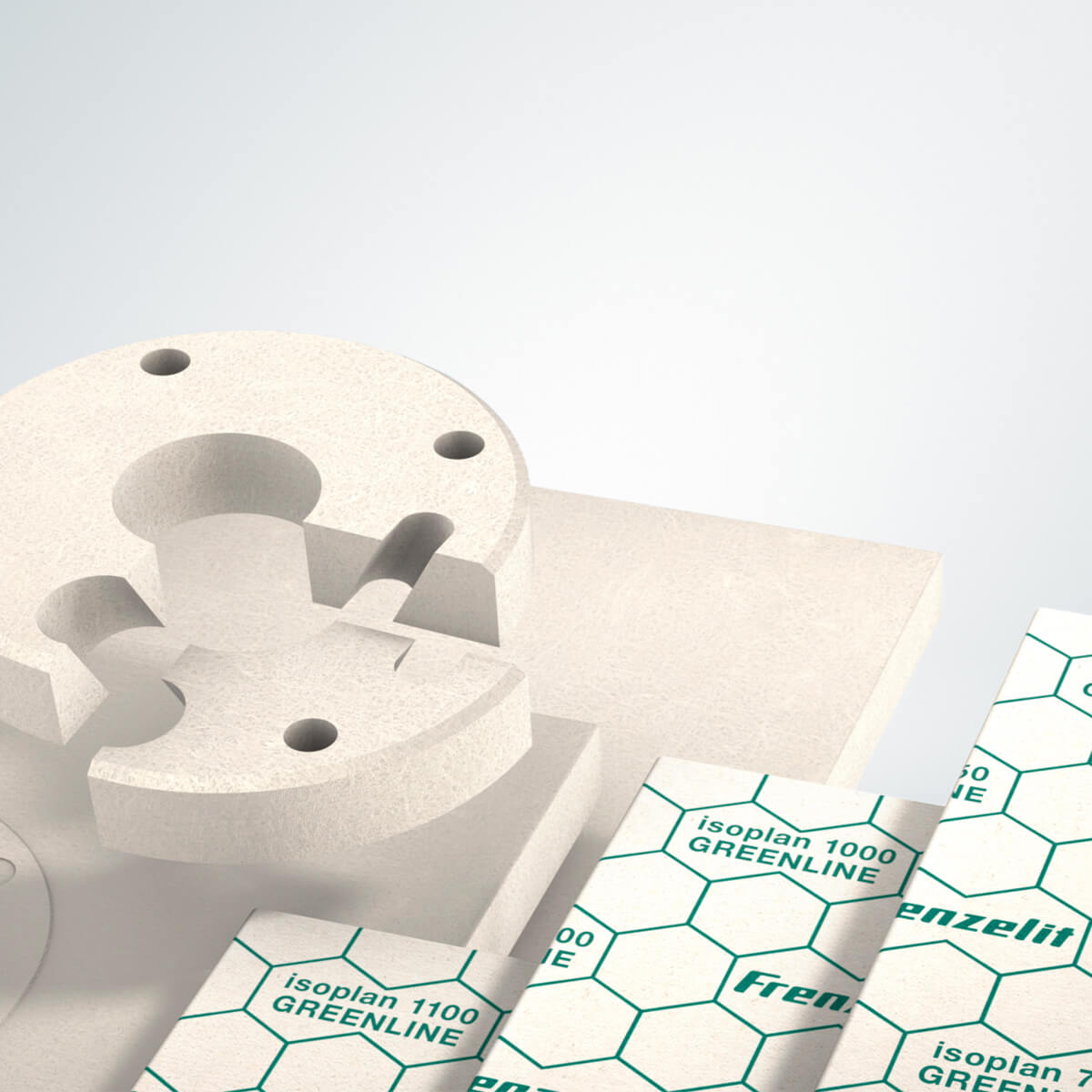

Versatile use

Due to its low thermal conductivity isoplan® is an excellent material for thermal insulation. isoplan® is also suited for electrical decoupling in low-voltage applications. Another field of application is acoustic damping. isoplan® can even be used in vibrating systems with full-surface lamination (e.g. with sheet metal). And with low leakage requirements and an internal pressure of max. 500 mbar isoplan® is also suitable as a high-temperature-resistant gasket material.